FL vertical fluidizing drier

The machine is main used for drying powder or granule from pharmaceutical ,foodstuff and chemical and so on industries.

- Description

- Inquiry

Introduction of Spray Drying Machine

After air is purified and heated, then it will be introduced from the bottom of induced-draft fan and passed through the screen plate of raw material. In working chamber, the state of fluidization is formed through stirring and negative effect. The moisture is evaporated and removed rapidly and the raw material is dried quickly.

Principle

The powder granule the container (fluidization bed) appears the state of fluidization. It is preheated and mixed with clean and heated air. At the same time the solution of adhesive solvent is fogged and sprayed into the container. It makes the some particles become granulating that contains adhesive. Being of unceasing dry through hot air, the moisture in the granulating is evaporated and the adhesive is solidification. The process is carried out continuously. Finally it forms ideal, uniform and porous granules.

Features

1) Because of powder granulating, the flow property is improved and the dust is reduced

2) Because of powder granulating, its solving property is improved

3) The mixing, granulating and drying processes can be completed in one step inside the machine

4) The operation of equipment is safe, because the anti-static filtering cloth is adopted

5) Operation personnel cannot be damaged if explosion takes place, because there is releasing hole.

6) Has no dead corner. Therefore the loading and unloading are quick, light and clean.

7) Meets the requirements of GMP

Applications

1. Pharmaceutical industry: tablet capsule, low sugar or no sugar granule of Chinese traditional medicine.

2. Foodstuff: cocoa, coffee, milk powder, juice of granulate, flavoring and so on.

3. Coating: protection layer, color, controlled release, film, or bowels solved coating of granules and pills.

4. Drying: powder or granule state of wet material

5. Other industries: pesticide, feed, chemical fertilizer, pigment, dyestuff and so on.

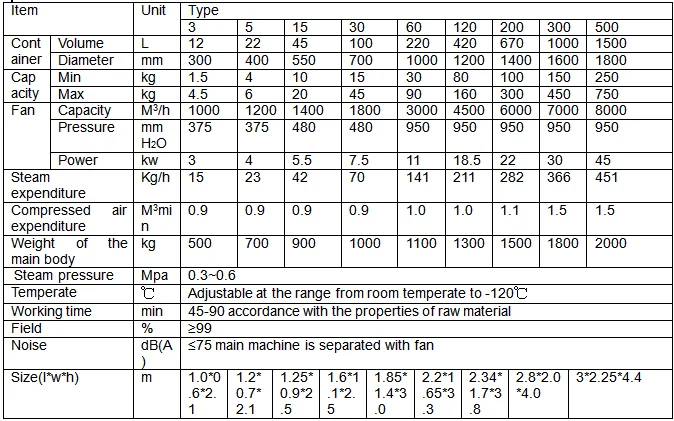

Techinical parameter

中文

中文 Русский

Русский